|

Kilns |

||

|

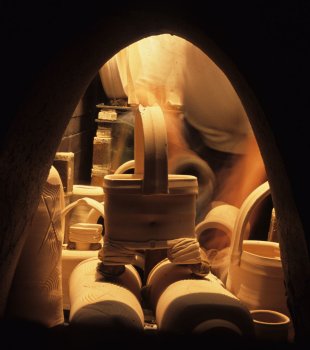

This wood

fired kiln was built in 1998 and was designed

by John Neeley of Utah State University and is based on a Japanese kiln.

The design of this kiln encourages ash deposits on the pots and creates

natural ash surfaces similar to those created in Anagama kilns. Many

pots are tumble stacked for more interesting results. Unglazed and

shino glazed pots are fired in this kiln. Firings are typically 42

hours long and use 2 to 3 cords of a mixture of hard and soft wood.

The kiln is easy to fire, creates very little black smoke, and reaches

temperature easily. See

Wood Fired to view pots

fired in this kiln. |

|

|

|

|

|

|

Hydraulic lift to raise and lower lid of Train kiln. Lid raises and then rolls back to open kiln. |

|

Anagama Kiln We named the kiln "Nezumigama". Nezumi is Japanese for mouse or gray and gama translates as kiln. This kiln was built in the Fall of 2005 during a kiln building and firing workshop led by Shozo Michikawa from Seto, Japan. It is a traditional Japanese Anagama because it has only one stoke hole (in the front) and has an empty chamber room behind the stacking area. I first fired this type kiln during my most recent visit to Japan. Michikawa has led workshops to build this kiln in several countries. See Anagama kiln building workshop - Click here |

||

|

|

|

Japanese Shino Gas Kiln This kiln was built with funding from a grant through the North Carolina Arts Council. On my most recent trip to Japan, I visited the Mino/Seto area where I was introduced to Naito, a well known potter who had worked for years with Shino. He showed me his Shino kiln and discussed his firing schedule. The significance of this kiln is its 18 inch thick walls, ceiling, floor and door made mostly with hard brick. The door is stacked each time after loading. The thickness is important for a slow heating and cooling, which helps develop the surface texture and colors. The firing lasts 100 hours and is fired to 1200 degree Celsius. At the end of the 100 hours, having remained at top temperature for 50 hours, an oxidation cooling of 20 degrees Celsius per hour is maintained until 850 degrees Celsius is reached. The kiln is then turned off and the cooling continues for 7 days. See Japanese Shinos to view pots fired in this kiln. |

||

|

|

|

|

Below: Stacking of latest firing in June 2009. Many pots in saggers to promote even temperature. See images on Japanese Shino page. |

||

|

|

|

|

|

|